The Bernard Rodriguez Journal

Exploring the latest trends and stories in news and lifestyle.

Tips to Prevent Print Cracking That are Easier Than You Think

Unlock the secrets to flawless prints! Discover simple tips to prevent print cracking that will transform your results effortlessly.

5 Simple Techniques to Prevent Print Cracking in Your Designs

Print cracking is a common issue that can compromise the integrity of your designs, but with the right techniques, you can significantly reduce the risk. One effective method is to ensure proper material selection. Using high-quality, flexible inks and substrates can provide better adhesion and durability, thus minimizing the chances of cracks. Additionally, adjusting your design elements, especially the areas with heavy ink coverage, can make a substantial difference. Consider using lighter colors or thinner lines in those areas to alleviate stress on the print.

Another key technique is to maintain proper print settings. Utilizing the correct temperature and pressure during the print process is vital for achieving optimal results. Furthermore, it’s essential to allow sufficient drying time between layers if you’re using layered printing methods. This can prevent the inks from smudging or cracking when pressed together. By implementing these simple techniques, you can help safeguard your designs against print cracking and ensure a more polished final product.

If you're a fan of Pokémon, you'll love exploring our pokemon shop, where you can find a variety of merchandise ranging from plush toys to trading cards. Our collection is perfect for both collectors and casual fans alike, offering something for everyone.

Understanding the Causes of Print Cracking: Tips for Avoidance

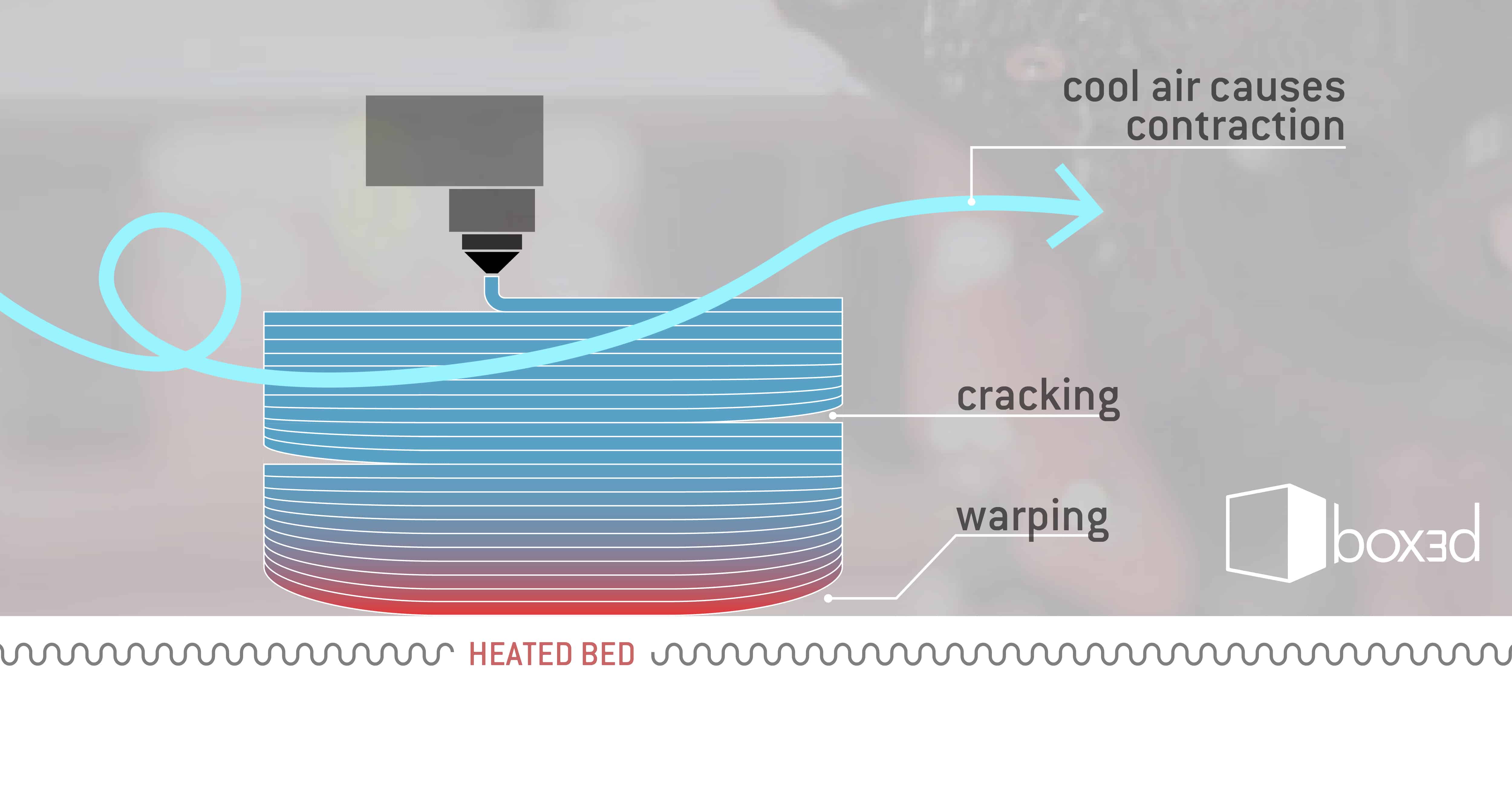

Print cracking, a common issue faced in various printing processes, can significantly affect the quality and longevity of printed materials. The primary cause of print cracking is the tension created during the drying process of the ink or coating. When the top layer dries faster than the underlying layers, it leads to stress and ultimately cracks. Factors such as the type of ink used, the nature of the substrate, and environmental conditions play a critical role in this. For instance, using a flexible ink on a rigid substrate can exacerbate the likelihood of cracking. Additionally, temperature and humidity levels during the printing process can further influence the drying speed, making it imperative to monitor these conditions closely.

To mitigate the risk of print cracking, consider the following tips:

- Opt for compatible materials: Always choose inks and substrates that work well together to ensure uniform drying.

- Control your environment: Maintain optimal temperature and humidity levels in your printing area to reduce stress on the printed materials.

- Implement proper curing techniques: Allow adequate time for the ink to cure before handling the prints, as this can prevent premature cracking.

Can You Really Prevent Print Cracking? Expert Tips You Need to Know

Preventing print cracking is a common concern for both manufacturers and consumers alike. Print cracking occurs when the printed design on a product, such as apparel or promotional items, starts to split or flake away from the substrate, compromising the aesthetics and longevity of the print. To effectively prevent print cracking, it’s essential to choose high-quality inks and materials that are specifically designed for the intended use. Additionally, proper curing techniques, such as using the correct heat settings and duration, play a crucial role in ensuring that the prints adhere well and remain durable over time.

Moreover, here are some expert tips to help you further reduce the risk of print cracking:

- Choose the Right Fabric: Opt for fabrics that have a smooth surface and good stretch recovery.

- Avoid Overloading with Ink: Too much ink can create rigidity, leading to cracking.

- Use Specialized Inks: Explore inks formulated for elasticity and flexibility to reduce cracking.

- Perform a Stretch Test: Always test your prints for durability by stretching the fabric before mass production.